Emulsifying and rubbing machine

Asthescience and technologydeveloping, the request of the products ishigher and higher. We adopt the advanced experience, combine the strong suit ofhomogenizer and rubbing machine, R&D out themultifunctionaldelicateemulsifying and rubbing machine series.It provides a solution for producing colloid or thehigh viscosity material which requests emulsifying and rubbing enough. It canbe used with emulsifying mixer or planet mixer and also can be usedindividually.

Asthescience and technologydeveloping, the request of the products ishigher and higher. We adopt the advanced experience, combine the strong suit ofhomogenizer and rubbing machine, R&D out themultifunctionaldelicateemulsifying and rubbing machine series.It provides a solution for producing colloid or thehigh viscosity material which requests emulsifying and rubbing enough. It canbe used with emulsifying mixer or planet mixer and also can be usedindividually.

Working elements:

The emulsifying & rubbing machine’s linear velocity can get to 21M/S. The rubbing module composed by a spud stator which has third stage adjusting clearance and a four stage circumrotating in high speed spud rotor. The rubbing clearance can be adjusted from 0.01mm to 2mmsteplessly according the producing request. The flute of the stator and rotor is more delicate and more delicate by steps. The different depth and direction increased the onflow of the hydro-. When the material goes through, it forms strong pressing, cutting, emulsifying, crushing, mixing, dispersing and rubbing. Then getting the delicate ultramicrosome. There is circular water outside the spud stator and in the outlet antrum and sealing parts.

usage:

Food industry:butter、jam、dairy products、vegetable proteins、animal proteins and various of food and beverage.

Chemical industry:Paints, pigments, dyes, paints, adhesives, detergents, synthetic leather, leather etc

Daily use industry:Toothpaste, detergent, shoe polish, senior cosmetics etc.

Medical industry:Syrup, nutrition, medicine, pastes pharmaceutical, biotechnology products, cod liver oil, all kinds of ointment etc.

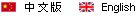

Dimension and technical parameters:

类型 |

流量 Flux |

转速 Speed |

功率 Power |

外形尺寸 Dimension |

||||

L/H |

RPM |

KW |

A |

B |

C |

D |

E |

|

RY-75 |

50~1,000 |

4,500 |

2.2 |

680 |

710 |

DN15 |

DN25 |

380 |

RY-100 |

300~3,500 |

3,800 |

4 |

700 |

750 |

DN32 |

DN50 |

420 |

RY-125 |

500~6,000 |

3,400 |

7.5 |

720 |

800 |

DN40 |

DN65 |

450 |

RY-160 |

1,000~15,000 |

2,500 |

15 |

820 |

950 |

DN50 |

DN80 |

450 |

RY-250 |

2,000~30,000 |

1,500 |

30 |

1,100 |

1,050 |

DN80 |

DN150 |

550 |

* 流量取决于设置的间隙和被处理物料的特性。 The flux is depending on the set clearance and the speciality of the disposed material. |

||||||||